【Lamp Core Technology Report 2201】Digital OLED taillights

If you want to evaluate one of the most memorable cars of 2021, the Audi A6 E-tron concept car must be among them. The A6 E-tron made its world premiere at the 2021 Shanghai Auto Show. The new car follows the concept of Sportback styling, adopts a subversive exterior styling, and comprehensively leads the drag coefficient, indicating that a new major change in the field of automotive design is poised to begin.

Particularly striking are the Audi digital OLED taillights. At a time when competition for LED lights is becoming increasingly fierce, Audi has come up with a new generation of digital OLED taillights with a variety of shapes and a more design. The entire tail light uses 26 digital OLEDs, each OLED has 60 zones, so that the lighting design has infinite possibilities.

Digital OLED technology has become ubiquitous on TV screens, and this time Audi is using it for car lights, while offering a customized light signature selection service.

At a time when car companies around the world are expanding their territory in other car lighting technologies, why is Audi still focusing on OLED technology and not changing its obsession with it?

Technical characteristics of digital OLED

OLED = the most uniform flood light

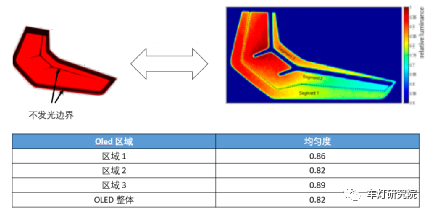

Unlike LED point light sources, one of the unique properties of OLED is that it can perfectly achieve flat lighting. Since light is produced uniformly in the organic phosphor layer, there is no need for any additional reflectors, fibers, or similar optical parts for light diffusion. Due to this essential characteristic of OLED, it is easy to achieve a plane lighting effect with a uniformity greater than 0.8 (uniformity = 1-(Lmax-Lmin)/(Lmax+Lmin))

OLED, the uniformity of flat lighting is difficult to achieve through the point light source scheme of LED. And there's a little more difficult: the spacing between the different partitions in a digital OLED panel is very narrow, which can be as narrow as <100μm, and at the same time there is a very high contrast ratio, with no light scattering and no string light between the different partitions. This feature has been well reflected in production projects such as the Audi Q5 and Audi A8 (pictured below).

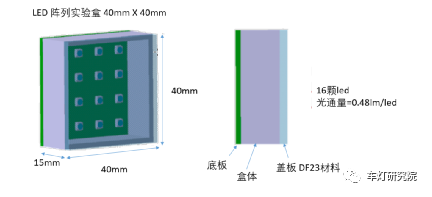

There has always been a technical challenge in the design of OLED = the highest light source in the design of automotive tail lights, how to find a technical solution with novel shape and high optical efficiency, and at the same time meet the low power and good reliability, so as to achieve a uniform light emitting plane lighting effect. As carbon neutrality becomes increasingly important, efficacy will play an increasingly important role in the design of automotive lights. OLEDs are essentially surface light sources that produce uniform surface light within their luminous region without the need for scattered optical elements, such as diffusion inner lenses. On the contrary, LEDs are point light sources, and specific surface light effects can be obtained with the help of micro-optical surfaces or scattering materials. However, the cost of this optical modification is the loss of optical efficiency. In order to compare the efficacy of LED/OLED, we tried to make a prototype of an LED test box with a size of 40mm x 40mm and 9 to 16 TOP LEDs inside.

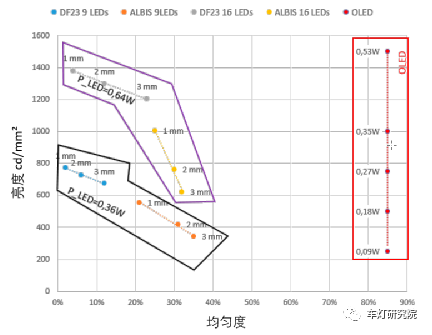

The distance from the LED to the cover is set at 15 mm, and the cover uses the commonly used optical diffusion materials ALBIS and DF23 to achieve a flat lighting effect. In order to ensure sufficient uniformity, we increased the thickness of the diffuser cover to 3mm. The results are shown in the figure below.

(Brightness vs. uniformity at constant power)

This is known from the test results in the figure above. Compared with the technical solution using LED plus scattering material inner lens, OLED has higher uniformity and lower power consumption. Increasing the scattering of the lens can certainly increase uniformity, but the brightness will decrease significantly. In the thickness range of OLED (<2mm), there is basically no LED solution that can match OLED in optical efficiency and uniformity. Refer to the latest dismantling of the Volkswagen ID.6.X Surface led tail light (refer to the research institute article Surface led-> conveyor belt), the thickness of the Surface led position light is nearly 7mm, in order to achieve the effect of uniform flood light, A terrifying 36.8W is used, which is almost equivalent to the power consumption of one low beam + high beam.

Digital OLED = Flexible Taillight Display Technology for Individual Differentiation and C2X Communication

The small spacing between OLED partitions and the high contrast ratio enable new lighting applications. The current production models still use only a small number of partitions (N<8), just like the Audi A8 and Q5, for position light animations. The Audi A6 E-tron is upgrading OLED to a high-division-count display. Proven processes and materials are used to produce lighting products that meet the reliability requirements of automotive lights.

The new digital OLED technology activates multiple independently controlled zones at random, and the brightness can change continuously. In the mass-produced new Q5, there are 3 digital OLED plates inside the taillight, and each OLED plate is made up of six zones, in other words, each taillight has 18 zones. When each OLED screen has more than 50 partitions, it can produce endless partition combinations. When an OLED is installed in a headlight, the pattern and appearance of the OLED can be changed by simply displaying information. Therefore, OLED gives the personality of the lights without the need to replace any lamp hardware configuration, as shown in the figure below, digital OLED can achieve a variety of exterior designs.

(OLED pattern change based on electronic drive control)

Another advantage of digital OLED displays is that each partition shape can be designed separately, eliminating the need to unify into regular partition shapes. As a result, partitions of very different shapes and sizes may be designed within a single digital OLED board. Moreover, the desired pattern can be formed directly through the partition design, without the use of a large number of pixels (such as miniLED screens), which require complex electronic drive modules, and the edges of the pattern can produce jagged pixels. In addition, the brightness value of the red OLED screen can already achieve ≥ 2.000cm/m2, which is much higher than other display solutions.

Using digital OLED, it is also possible to develop a universal OLED screen that can be used in many car models, while still retaining a unique exterior design for each model. The general-purpose OLED screen can greatly reduce the production cost and provide application possibilities for other entry-level models.

In addition to the light signal function, digital OLED technology can also be used as an interactive display, for example, to provide interactive information for the rear car and pedestrians. In compliance with current regulations, digital interactions in the lamps or in connected vehicles and infrastructure can also contribute to driving safety, especially in the field of autonomous vehicles. Other existing LED display solutions, whether in terms of package size, lighting uniformity and contrast, or flexible partition settings, compared with digital OLED solutions, have obvious disadvantages. As a result, digital OLEDs will provide us with endless opportunities and possibilities from design to personalization, from interactivity to security.

The real technological revolution of digital OLED also lies in the combination of digital partitioning with flexible substrate technology. Nowadays, all mass-produced OLED taillights use flat glass substrates, and it is difficult to integrate flat OLED panels into the free-form design of the lights. If OLed is to be used more widely, it needs to match the free-form shape of the car. Therefore, flexible digital OLED may greatly extend the use of space in car lighting, or even cover the entire tail light.

Of course, it is not easy for the automotive lighting industry to use Oled flexible substrate technology, and it must be able to meet the reliability requirements of the car. But now flexible OLED screens have been widely used in mobile phones, and the price is becoming more and more affordable, and the application in car lights will be just around the corner.

The color point stability and color uniformity at any angle will make the flexible digital OLED screen a unique light source for taillights, which cannot be imitated and matched by any other light source scheme, or will become the most flexible display solution in the automotive lighting industry.

Summary and outlook of digital OLED

Several models that have already been mass-produced have proven that there is no risk associated with OLED use in headlights. BMW, Mercedes-Benz and Audi are all using this innovative technology solution. Of course, to use it in large quantities, OLED needs to significantly reduce costs through cost control and modularization. Once the OLED is digitalized, it will achieve both the individual differentiation of the tail light design and the communication capability of the Car-2-Car, which is difficult to achieve with other light source solutions, and the digitization will not increase the production cost of the OLED, so the digital OLED will start to become attractive compared to other digital display solutions. Of course, flexible digital OLED technology will further enhance the integration and visibility of OLED in the field of automotive lighting.

Audi, the leading light design vane in the automotive industry, will undoubtedly lead more car brands to adopt digital OLED technology and open up a broader design space for automotive tail lamp styling design by using highly uniform and high-contrast digital OLED combination lamps for automotive tail lights.